Celebrating 90 years! #2: Massilly-Franpac

Celebrating 90 years of existence by sharing the stories of the men and the women who have made, and continue to make, la belle-iloise. Meeting them, asking them questions, going through their lives. That's what we're bringing you, in images and words, to spend a moment together on this anniversary.

Today, join us in Douarnenez and dive into the world of Massilly-Franpac, a local, long-standing partner of la belle-iloise.

For four decades, our unmistakable coloured tins were mostly produced here at Massilly-Franpac. For this anniversary year, we felt it was time to visit and show you their expertise. So off we go to Finistère-Sud, less than a two-hour drive from Quiberon, with our favourite documentary photographer, Clément Chapillon.

The Massilly group is a family company through and through, and French to boot. It is a world leader in metal packaging. Having built up valuableknow-how since 1911 in this field, Massilly now has 25 subsidiaries abroad and produces tins, lids for jars and decorative boxes for companies worldwide. In Brittany, Masilly is represented by Franpac, a company in Douarnenez that has specialised in tins for preserving fish since 1912.

“It’s the season for anniversaries for us too. Massilly celebrated 110 years of business last year, and Franpac, too, is celebrating its 110th anniversary this year. Like la belle-iloise, our companies are old-timers!” addedGilles Tourillon, Sales Director at Massilly-Franpac, as he greeted us to take us on a tour of the factory.

Massilly aims to “uphold, preserve and promote natural products and its customers with high-quality, safe and recyclable metal packaging.” To thisend, the Douarnenez factory has three production workshops: printing, tins and bases.

TEST PRESS

The photoengraving workshop and the test press.

Didier Lastennet and Jean-François Lagadec are test technicians and colourists. A traditional press takes pride of place in the workshop, reminiscent of that of an artist. They produce proofs by hand on this press to colour each metal tin that will be manufactured and printed. Like painters, they mix pigments and inks and do their best to balance colours. It is about finding the right shade with precision, the ideal hue for each product to illustrate every one of la belle-iloise’s recipes in the best possible way.

Metal proof prints are obtained with press ink rollers,

and once the proofs have been approved, printing takes place on an industrial scale using innovative technology

Didier Lastennet spreading the ink on the rollers.

Jean-François Lagadec preparing the photoengraving plates.

With the Pantone colour chart to hand, they find exactly the colours we want. From that moment on, they produce proofs for validation.“You either like it or you don’t, and if not, we start over. That’s my job. If the client has not approved the tin and validated the proofs, we must continue to find the perfect colour. Sometimes it’s the tiniest of things, a slightly different shade,” Didier tells us.

Didier Lastennet checking the result under a daylight lamp.

The tests are a hit for our iconic Saint-Georges sardines!

PRE-PRESS

In the office next door, Thierry Diraison, Pre-Press Manager, receives the graphical files sent by the canneries, defines the stages in the printing process, and goes about setting up all the technical means required to print the tins on an industrial scale.

Thierry Diraison, Pre-Press Manager, in his office.

The company keeps the validated proofs as a template for the machines

Didier, François and Thierry all joined in 1985. They make a good team –“a right bunch of old jokers” –where a genuine brotherly spirit reigns.“We are the Franpac family. In the 1980s, the company hired many people, and a whole new generation arrived here. The Massilly group had just bought out Franpac and made investments. That’s why the three of us came here at the same time 37 years ago.”

After watching the manual production of our iconic Saint-Georges tin, we were joined by Valérie Bindschedler, Marketing Director at Massilly and the great-granddaughter of the founder, Robert Bindschedler. And so our factory tour continued, along with a few questions, interview style.

« The company grew with everyone».

Valérie Bindschedler, Massilly’s Marketing Director and the founder’s great-granddaughter

- How did the adventure that is Massilly start?

Valérie: It all started in 1911 when my great-grandfather bought an old mill in the village of Massilly. He installed a turbine battery in the mill to produce electricity, retrieving tin from tinplate waste by electrolysis. Yes, we were already recycling even back then! A few years later, he started transforming tinplate to produce household items.

Nowadays, our production sites have cutting-edge technology, and our teams work daily to produce metal packaging that is always that bit lighter and safer. At Massilly, we are convinced that our tins have everything to meet today’s challenges and build the world of tomorrow: feed as many people as we can in the safest and healthiest way possible; limit resource waste by making it easy to preserve and protect goods; and safeguard our planet for the generations to come thanks to infinitely recyclable metal. Few people fully understand the benefits of tins. It’s a form of packaging for the future and we can be proud of that.

PRINTING

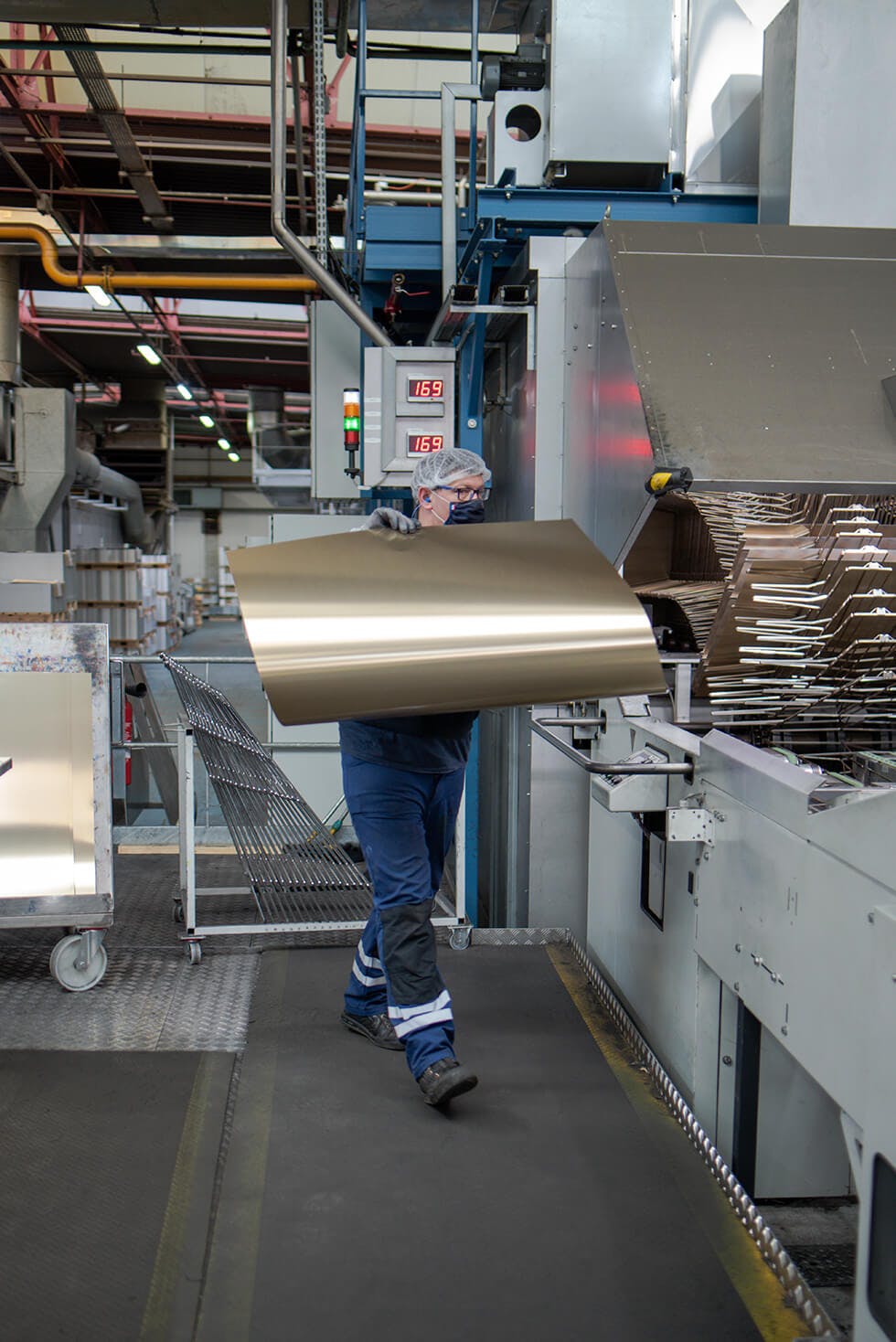

This reel of tinplate weighs 12 tonnes and is 7 km long!

The cutting tool cuts the huge reel into sheets of the right size for the tins or bottoms.

Racks upon racks of metal sheets with razor-sharp edges.

- What characterises Massilly?

Gilles: We are a bit different from our peers in the world of packaging. Massilly continues to be a family company. We value the well-being of our workers as much as customer satisfaction. Unlike our competitors, backed by pension funds, we are not hell-bent on results. And I think that’s a great thing. Our approach is not at all the same. We want to be involved in building a more sustainable world, and all our projects are reviewed in terms of corporate social responsibility. We have a true enterprising philosophy: we invest in the company and aim to have activities with the least possible impact in all areas. We want to provide solutions and imagine synergies between companies to work together and be more effective. There are lots of things to consider. Tins are endlessly recyclable products: a real blessing, but we need to go further still.

Ready, steady, go! Printing starts on this metal sheet.

Cédric Massart, Offset Line Manager, in front of the print control table.

As printing progresses, printed sheets are sampled for inspection under a magnifier.

A metal sheet printed with the la belle-iloise design for our sardines with olive oil and lemon.

- In your view, are tins a 21st-century product and a product of the future?

Thierry: With recent events, we have seen that tinned goods do indeed have their place in today’s world. Some people stock up; others eat them daily because it’s part of their culture. They are a healthy product, provided there are no preservatives. The food inside is preserved using sterilisation, which is achieved by heating the packaging, in turn destroying any germs. That is how nutrients are preserved without preservatives for many years. During turbulent times, tinned goods are a sure thing, a safe investment.

Gilles: Tinned goods go to the moon, to space. Thomas Pesquet [the astronaut] even took some! Tinned food has accompanied and continues to accompany great discoveries. Without them, people would not have been able to explore the world as they did. So of course it’s a product of the future. What’s more, it’s 100% recyclable, and endlesslyso. Metals are incredible materials —you don’t need energy to store tinned goods. When there are environmental or societal issues or conflicts as we see today, one of the first reflexes is to stock up on tinned goods. So it’s a product of the future, no doubt about it.

With COVID-19, we saw an 8–10% rise in the volumes of tinned products consumed during 2020. Eating at home went through the roof because it’s pretty handy to be able to open tins for balanced meals when you have to eat twice or three times a day. As such, tinned goods saw a boom in demand, whether for fish, prepared dishes or vegetables.

Over time, recipes have improved and are more and more elaborate. There has been an enormous amount of research and development in tinned goods. A huge number of new recipes were developed, creating a real dynamic for tinned goods, it’s obvious to see. I am sure that tinned goods have a bright future. But like any product, you need to be exacting and have high-quality ingredients and great preparations ifcustomers are to buy them.

BASES WORKSHOP

The metal sheets are cut up into strips and presented under two successive presses to get the base we want.

A ring pull is then seamed onto the upper side of the tin, just what you need to open it!

All metal waste can be recycled.That means you don’t waste a bit of this precious, endlessly recyclable raw material.

- And speaking of Brittany, does the company have strong ties with the local area?

Gilles: When it comes to Franpac there’s no question about it! We’re in Douarnenez after all! And the Massilly group is from the Bourguignon region; its head office continues to be in Bourgogne, in the village of Massilly, where our first factory still stands. There’s a strong attachment to the different regions in which our various sites are located. We aim to settle into the areas as best as possible to have a positive impact.

- What does it mean to be Breton?

Gilles: Well, I come from Nantes, but I think I’ve become a Breton over the years. The way of life in Brittany is unmistakable. Courage and hard work are very strong markers here. But you should ask the opinion of a true Breton, such as Didier.

Didier: No one is as welcoming as the Bretons. (Laughter)

Thierry: The Bretons have a strong attachment to their region and are people of their word. Once you’ve gained their trust, they stick by it. They are honest through and through. Even if they are not always easy to approach at first and can be rough and ready, once they’ve let their guard down, it’s for life.

Marie-France Le Bris, quality control operator checking that the bottoms of the tins are conforming, and Gilles Tourillon.

TINS WORKSHOP

Last stage in the manufacturing process: the tins and bottoms are packaged onto pallets, ready forshipping to the companies that ordered them.

- A question for you, Gilles.You’ve been working at Franpac since 1992.How will you celebrate your 30th work anniversary?What makes a good anniversary?

Oh, we’ll open a few la belle-iloise tins. (Laughter) I’m not going to be very objective here, but I can’t get enough of the la belle-iloise spreads for an aperitif! All the tuna and mackerel spreads are extraordinary. At home, it’s our Sunday treat. When we have friends over, we get some out every time. And I can tell you that we’ve got copycats now! Even just the one la belle-iloise sardine fillet, sliced into half on a slice of toast, can bring a tear of joy to my eye!

Gorgeous tins, full of goodness, the fruit of this partnership of excellence between Massilly-Franpac and la belle-iloise.

When you see how much expertise goes into making tins and how invested the teams are, you can understand why tins have survived the test of time since their invention in 1795 by the French inventor Nicolas Appert. And besides that, we tell ourselves that in the future, once you have tasted one of our tinned goods, you’ll think twice before throwing the tin out. We’re confident you’ll recycle it or find a new use for it to ensure it continues to have a very long life!

A huge thank you to Gilles Tourillon, Thierry Diraison, Didier Lastennet, Jean-François Lagadec, Marie-France Le Bris, Cédric Massart and Valérie Bindschedler for their warm welcome.